The Ultimate Guide for B2B Purchasers in Custom Coffee Mug Industry

In the world of corporate branding, personalized merchandise like custom coffee mugs has become a vital tool for businesses to promote their brand. A well-designed coffee mug, adorned with a company’s logo, not only serves as a functional item but also acts as a marketing asset, helping businesses keep their brand in front of customers every day. If you’re a B2B purchaser in the ceramic products sector, understanding how logos are put on coffee mugs can help you make informed decisions about which methods are best suited for your business and your clients’ needs.

In this article, we’ll take a deep dive into the various techniques used to print logos on coffee mugs, evaluate their advantages and disadvantages, and offer guidance on choosing the right option for large-scale B2B orders. Let’s explore the process, techniques, and benefits of different logo application methods, along with tips to help you procure the best custom coffee mugs for your business.

1. Understanding the Basics of Logo Printing on Coffee Mugs

Before diving into the techniques, it’s essential to understand the basic steps involved in logo printing on coffee mugs. These steps generally include:

- Designing the Logo: The client or business provides the logo design, which can include colors, size specifications, and positioning on the mug.

- Choosing the Mug Type: Different mug types (ceramic, glass, porcelain, etc.) may require specific printing techniques.

- Selecting the Printing Technique: Depending on the budget, design complexity, and mug material, different techniques are used to apply the logo.

- Production Process: The chosen method is then applied during or after the production of the mug, followed by drying, curing, or baking depending on the technique.

The process might vary depending on the manufacturer and the type of logo printing you choose.

2. Main Techniques for Logo Application on Coffee Mugs

Several printing methods are available for applying logos on coffee mugs. Each technique has its benefits and limitations, depending on factors such as cost, durability, color fidelity, and design complexity. Below, we’ll cover the most popular methods.

A. Screen Printing

Process:

Screen printing involves using a mesh stencil to transfer ink onto the mug’s surface. Each color in the design requires a separate screen, and the inks are layered sequentially.

Advantages:

- Cost-effective for large bulk orders.

- Ideal for simple, bold designs with fewer colors.

- Can be used on curved surfaces like mugs.

Disadvantages:

- Limited to one to four colors.

- Complex designs or intricate details are difficult to replicate.

- Inks may fade after repeated use or washing.

Best Use:

Screen printing is great for simple logo designs, especially for orders in large quantities where cost efficiency is crucial. It’s often used for promotional mugs or giveaways.

B. Pad Printing

Process:

Pad printing uses a silicone pad to transfer the logo from an etched plate onto the mug. The pad picks up the ink from the plate and presses it onto the curved surface of the mug.

Advantages:

- Excellent for printing on curved surfaces and small areas.

- Can handle fine details and multi-colored designs.

- Works well on a variety of materials like ceramic, plastic, and glass.

Disadvantages:

- Limited to smaller print areas.

- Less durable than other methods; logos may fade over time with extensive use.

Best Use:

Pad printing is perfect for small logos or designs on coffee mugs with intricate details. It’s a versatile option for orders that require high-quality, detailed prints.

C. Digital Printing

Process:

Digital printing involves applying the logo directly onto the mug using specialized printers that can handle high-resolution, full-color designs.

Advantages:

- High-quality, vibrant, full-color printing.

- Can handle complex designs with gradients, shading, and photographic detail.

- Fast and efficient for small and medium orders.

Disadvantages:

- Not as cost-effective for large bulk orders.

- Durability may vary depending on the type of coating used to protect the print.

Best Use:

Digital printing is ideal for B2B orders that require visually intricate designs, such as photo-quality logos or multi-colored artwork. It’s perfect for smaller or limited-edition runs.

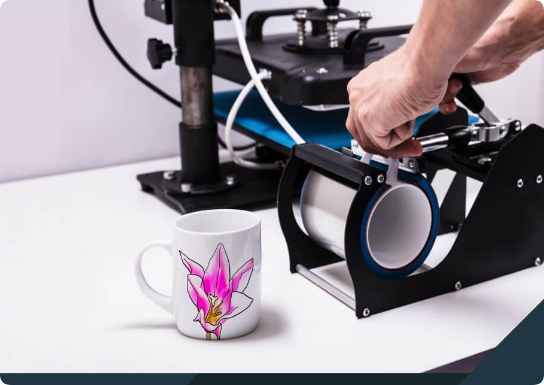

D. Sublimation Printing

Process:

In sublimation printing, the logo is first printed onto a special paper using sublimation ink. The design is then transferred to the mug using heat and pressure, which turns the ink into gas and embeds it into the mug’s coating.

Advantages:

- Full-color printing with excellent durability.

- Logos won’t fade, crack, or peel over time.

- Can print edge-to-edge and cover the entire surface of the mug.

Disadvantages:

- Only works on sublimation-coated mugs, typically white in color.

- More expensive compared to screen or pad printing for large orders.

Best Use:

Sublimation printing is ideal for vibrant, full-color designs that cover the entire mug. It’s perfect for custom projects where the longevity and quality of the print are paramount.

E. Laser Engraving

Process:

Laser engraving uses a high-powered laser to etch the logo into the surface of the mug. This method creates a permanent, raised texture where the logo is engraved.

Advantages:

- Extremely durable; logos won’t fade or wear out.

- Elegant, high-end look, perfect for corporate gifts or premium products.

- Suitable for metallic mugs or those with unique finishes.

Disadvantages:

- Limited to monochromatic designs (no color).

- More expensive than other printing methods.

Best Use:

Laser engraving is a premium option for high-end mugs, often used in corporate gifting or luxury branding where durability and aesthetics are essential.

3. Comparison of Logo Printing Techniques

To help you decide which method best suits your needs, here’s a comparison of the key factors for each technique:

| Method | Color Range | Durability | Cost for Large Orders | Complexity of Design | Best Use |

|---|---|---|---|---|---|

| Screen Printing | 1-4 colors | Moderate | Low | Simple designs | Bulk promotional mugs |

| Pad Printing | Multi-color (limited) | Moderate | Moderate | Fine details | Small logos on curved surfaces |

| Digital Printing | Full-color | Moderate | Moderate | Complex, photographic | Small-medium orders, intricate designs |

| Sublimation | Full-color, vibrant | High | High | Complex, edge-to-edge | Full-surface designs, premium prints |

| Laser Engraving | Monochrome | Extremely high | High | Simple, elegant | Corporate gifting, luxury branding |

4. Key Considerations for B2B Purchasers

When selecting a printing method for your custom coffee mugs, several factors should be considered to ensure you make the right decision for your business or client:

- Order Volume: Some techniques, such as screen printing, offer better cost-effectiveness for larger orders, while methods like sublimation are more suitable for smaller, high-quality batches.

- Design Complexity: If your logo features intricate details, gradients, or full-color imagery, digital printing or sublimation may be the best option.

- Durability Requirements: For logos that need to withstand frequent washing and usage, consider sublimation or laser engraving, which offer superior durability compared to traditional printing methods.

- Budget: Each technique comes with its own cost implications. Screen and pad printing are generally more affordable for bulk orders, while sublimation and laser engraving come with a higher price tag due to their premium quality.

5. Why Choose EKA Ceramic for Your Custom Logo Mugs?

At EKA Ceramic, we specialize in creating high-quality, customizable ceramic coffee mugs for B2B purchasers. Whether you’re a large-scale distributor, corporate brand, or retailer, we offer comprehensive services, including various logo printing options to meet your specific needs. Our team of experienced professionals is committed to delivering premium products tailored to your branding requirements.

What sets us apart?

- One-stop service: From product design to logo application, we provide end-to-end support.

- Flexibility: Whether you need a small batch or a large bulk order, we can accommodate your order size.

- Quality Assurance: All our mugs undergo rigorous quality control to ensure they meet your standards.

- Global Delivery: We offer shipping and logistics services worldwide, ensuring timely delivery to your location.

Conclusion

Choosing the right method to apply logos on coffee mugs can be a game-changer for your business. From cost-effectiveness to design complexity and durability, understanding the nuances of each printing technique allows you to make informed decisions that align with your branding strategy. At EKA Ceramic, we help B2B purchasers navigate the world of custom mugs with expert advice and high-quality products. Get in touch with us today to discuss your custom mug project and discover the best logo application options for your business.