Understanding the Craft, the Function, and the Brand Impact

In the world of ceramic tableware, the glazed finish is one of the most critical elements that shape both the visual appeal and practical performance of a plate. It serves as a key factor in how customers perceive product quality and usability—from aesthetics and touch to durability and hygiene.

This article takes a deep dive into the different types of ceramic plate glazes, their characteristics, technical details, and functional advantages. With clear comparisons and insights, it helps kitchenware buyers, giftware wholesalers, and cross-border sellers make well-informed decisions that enhance product value and user experience.

What Is a Ceramic Glaze, and Why Does It Matter?

A ceramic glaze is a glassy coating applied to the surface of a ceramic body. It is fired at high temperatures to form a smooth or textured layer that offers waterproofing, stain resistance, and decorative effects. The glaze plays a dual role: protecting the surface and creating a desired finish—whether glossy, matte, rustic, or artistic.

Simply put, a glaze is where form meets function, and where product quality meets branding potential.

Common Types of Ceramic Glazes: A Professional Comparison

Each glaze finish brings unique aesthetic and performance traits. The following table provides a detailed comparison of popular ceramic glaze types, highlighting their surface texture, technical complexity, durability, and practical usage:

| Glaze Type | Surface Texture | Craft Complexity | Scratch Resistance | Ease of Cleaning | Color Expression | Best Use Scenarios |

|---|---|---|---|---|---|---|

| Glossy Glaze | Smooth and shiny | Low | Medium | High | Vivid, transparent | Daily use, modern collections |

| Matte Glaze | Soft, non-reflective | Medium | High | Moderate | Subtle, natural | Minimalist or Nordic styles |

| Rustic Matte (Stoneware) | Grainy, rough feel | High | High | Moderate | Raw, earthy | Vintage, artisan themes |

| Crackle Glaze | Visible crack lines | High | Medium | Moderate | Unique, classical | Decorative plates, gift items |

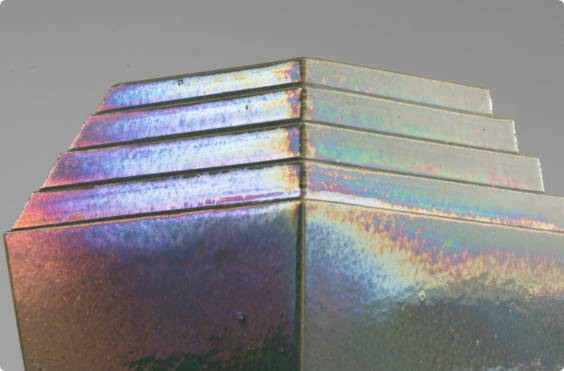

| Reactive Glaze | Layered gradients | High | High | Moderate | Deep and complex | Artistic ceramics, boutique |

The Science Behind Ceramic Glazes: Craft Meets Chemistry

1. Glaze Composition

Most glazes are made from a mix of silica, alumina, alkali metals, and coloring oxides. The specific formulation affects hardness, melting point, and visual clarity.

- High-silica glazes → smoother and harder

- Metal oxides → used for color variations and reactive effects

- Copper/iron oxides → responsible for blue, green, or metallic tones

2. The Role of Firing Temperature

Glaze performance and appearance change dramatically with firing temperature:

- High-fire glazes (>1200°C): dense, water-resistant, highly durable

- Mid-fire glazes (1000–1200°C): good color control but may show surface pinholes

- Low-fire glazes (<1000°C): more decorative, less durable for functional ware

For example, reactive glazes require precise high-temperature firing to achieve their signature gradient effects, while matte glazes demand careful temperature control and atmospheric conditions to maintain their softness.

3. Key Functional Properties Affected by Glaze

| Performance Factor | Description |

|---|---|

| Scratch Resistance | Depends on glaze hardness and thickness; rustic matte tends to resist scratching well |

| Cleaning Ease | Relates to surface smoothness; glossy and high-fire glazes are easiest to clean |

| Color Stability | Influenced by coloring agents and kiln atmosphere; oxidation gives brighter tones |

| Food Safety | Lead- and cadmium-free glazes are required; high-fire glazes often meet global standards |

| Batch Consistency | Matte and crackle glazes show more variation; good for artisanal branding, less ideal for mass retail |

How to Choose the Right Glaze for Your Market

The ideal glaze depends on your target audience, usage context, aesthetic identity, cost control, and branding direction. Here’s a practical guide:

- Mass retail or gift sets → Glossy or matte glazes offer consistency, durability, and broad appeal.

- Niche eCommerce brands → Crackle or reactive glazes create uniqueness and handmade appeal.

- For visual impact in photos → Reactive glazes offer color layering and natural lighting effects.

- For sustainable product lines → Matte glazes with natural materials pair well with eco-conscious branding.

FAQ – Frequently Asked Questions About Ceramic Glazes

Q1: Do matte glazes show water spots or fingerprints more easily?

Yes. Matte glazes have a porous surface texture that may reveal marks more clearly. However, using specialized formulations or double firing can reduce this effect significantly.

Q2: Can reactive glazes be consistently produced in bulk?

Yes, with standardized glaze recipes and kiln control. Professional ceramic factories can achieve reliable color control and minimize batch-to-batch variations through precise firing curves.

Q3: Are crackle glazes waterproof?

Traditional crackle glazes may absorb moisture due to surface fissures. Modern techniques—like sealing agents and double firing—can significantly reduce water absorption, making them safe for non-immersive use.

Q4: Is it possible to customize glaze colors to match a brand’s palette?

Absolutely. Many ceramic OEM manufacturers offer custom glaze color development services. Tailored color-matching is now a key value-add in ceramic tableware branding and private labeling.

Final Thoughts: Glaze Is the Soul of Ceramic Design

The glaze on a ceramic plate is more than a finish—it’s the interface between art and function, between visual identity and daily use. Understanding the materials, processes, and market implications of glaze selection can give your brand a decisive edge in both performance and perception.

Whether you’re planning to create your own tableware series or sourcing custom ceramic plates for retail or gifting, mastering glaze finishes is the first step toward product distinction.

EKA is a ceramic tableware manufacturing factory based in China, offering OEM and ODM services to kitchenware brands, gift suppliers, and eCommerce sellers worldwide. We specialize in a wide variety of glaze types, including matte, glossy, crackle, and reactive finishes. Our team supports custom glaze formulation, low-MOQ production, and consistent quality across batches.

📩 Ready to explore custom ceramic glazes for your next product line? Contact us today and start crafting your signature finish.