Ceramic bowls are a staple in kitchens and dining tables worldwide, offering a balance of aesthetic appeal and functionality. However, for B2B purchasers, it’s essential to evaluate ceramics comprehensively, from raw materials and production processes to their suitability in different markets and consumer requirements.

This article provides an in-depth analysis of ceramic bowls, covering their composition, design, production techniques, market-specific import/export standards, and consumer considerations like safety, durability, and environmental impact.

1. Raw Materials of Ceramic Bowls

The quality and performance of ceramic bowls begin with their raw materials. Key components include:

- Clay: The primary ingredient, which determines the strength and texture of the ceramic. Kaolin, ball clay, and other types are used depending on the desired bowl type (e.g., porcelain vs. stoneware).

- Feldspar: Acts as a flux, reducing the melting point of the clay and ensuring durability.

- Quartz: Enhances the rigidity and thermal resistance of the final product.

- Glaze: A protective and decorative coating, which can be glossy, matte, or textured, and provides a food-safe barrier.

Insight for B2B Buyers: Ensure that the clay and glaze used are lead-free and meet international food safety standards.

2. Design and Decoration

Patterns and Surface Finishes

Ceramic bowls can be customized with a variety of patterns and finishes:

- Hand-Painted Designs: Offer a premium, artisanal appeal.

- Decal Transfers: Ideal for mass production, enabling consistent designs.

- Embossed or Engraved Patterns: Add texture and depth to the bowl’s surface.

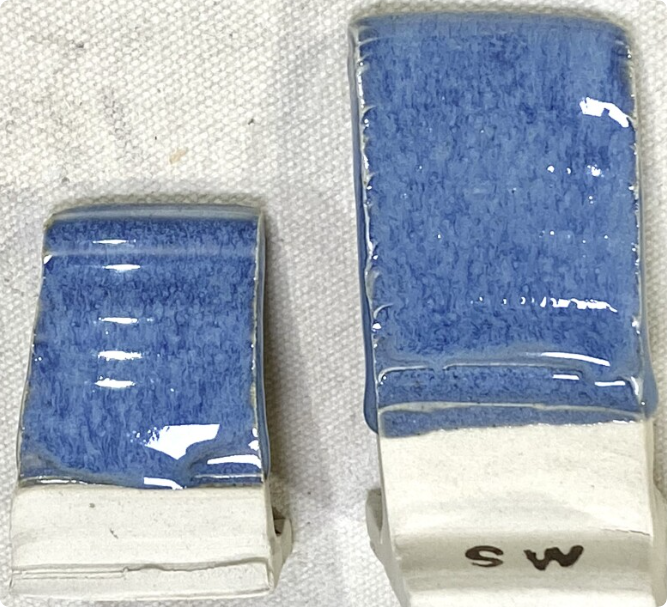

Common Glazing Techniques:

- Glossy Glaze: Enhances colors and patterns but may show scratches over time.

- Matte Glaze: Offers a modern look, preferred in minimalist designs.

- Reactive Glaze: Creates unique color variations, popular in rustic or artisanal collections.

Consumer Preferences: In markets like North America and Europe, minimalist and eco-friendly designs are trending, while Asian markets often prefer vibrant, traditional patterns.

3. Production Process of Ceramic Bowls

The manufacturing process influences the quality and performance of ceramic bowls. Key steps include:

- Shaping: Clay is shaped using molds, wheel-throwing, or slip casting techniques.

- Drying: The shaped clay is dried to remove excess moisture.

- Firing: The bowls are fired in kilns at temperatures ranging from 1,200°C to 1,400°C.

- Single Firing: Used for cost-efficient production.

- Double Firing: Ensures higher durability and finish quality.

- Glazing and Decoration: Bowls are coated with glaze and decorated before a final firing.

Procurement Tip: Choose suppliers who employ modern kilns with energy-efficient technologies, as they produce consistent results and align with sustainability goals.

4. Global Import and Export Requirements

Regulatory Standards by Region

| Region | Key Standards | Focus Areas |

|---|---|---|

| EU | REACH compliance, EN 1388 (leachable lead and cadmium limits) | Food safety, eco-friendly production |

| USA | FDA regulations, California Proposition 65 (lead and cadmium restrictions) | Safety for microwave and dishwasher use |

| Asia | Country-specific standards (e.g., China GB 4806 for food contact materials) | Durability, affordability, cultural design |

| Middle East | GCC Standards Organization (GSO) certifications | Thermal resistance, Islamic design motifs |

Insight for Exporters: Highlight compliance with these regulations in marketing materials to build trust with international buyers.

5. Consumer Considerations

Microwave and Dishwasher Safety

- Most ceramic bowls, especially those made of porcelain or high-fired stoneware, are safe for microwave and dishwasher use.

- However, bowls with metallic decorations or low-quality glazes may not be suitable.

Tip for Purchasers: Clearly label whether the bowls are microwave/dishwasher-safe, as this is a key selling point in many markets.

Child Safety

Ceramic bowls designed for children must meet stringent safety standards:

- Lead-free glazes.

- Chip-resistant designs to prevent sharp edges if broken.

Environmental Impact

- Sustainability: Ceramic bowls are reusable, long-lasting, and made from natural materials.

- Recyclability: While ceramics are not biodegradable, they can be crushed and reused in construction or pottery.

6. Advantages of Ceramic Bowls

Durability and Versatility

High-fired ceramic bowls are resistant to thermal shock, making them suitable for hot and cold dishes.

Aesthetic Appeal

Ceramic bowls are available in a wide range of designs, catering to both luxury and everyday markets.

Eco-Friendliness

Compared to plastic or melamine, ceramics have a significantly lower environmental footprint.

7. Challenges of Ceramic Bowls

Fragility

Ceramic bowls are prone to chipping or breaking, especially during shipping. Proper packaging and handling are essential for reducing damage rates.

Cost Considerations

The production of high-quality ceramics involves significant energy and labor, which can increase costs. Bulk procurement may help mitigate this.

8. Comparison: Ceramic Bowls vs. Other Materials

| Property | Ceramic Bowls | Glass Bowls | Plastic Bowls | Metal Bowls |

|---|---|---|---|---|

| Durability | Moderate to High | Moderate (breakable) | Low to Moderate | High |

| Microwave Safe | Yes (most types) | Yes | No | Limited (depends on coating) |

| Aesthetic Appeal | High | Moderate | Low | Low |

| Environmental Impact | Sustainable | Recyclable | Unsustainable | Recyclable |

| Cost | Moderate to High | Moderate | Low | Low to Moderate |

9. Recommendations for B2B Purchasers

- Material Choice

- Porcelain: For premium markets, offering fine designs and high durability.

- Stoneware: Suitable for mid-range markets, combining strength and affordability.

- Compliance Focus

- Ensure products meet the safety and quality regulations of target markets.

- Packaging Solutions

- Use shock-resistant and eco-friendly packaging materials to minimize breakage during transit.

- Customization Options

- Invest in designs that align with cultural or regional preferences for higher consumer appeal.

Conclusion

Ceramic bowls offer a compelling combination of functionality, aesthetics, and sustainability, making them an excellent choice for both domestic and commercial use. For B2B buyers, understanding the nuances of materials, design, production, and market requirements ensures successful procurement and customer satisfaction.

By aligning product offerings with global standards and consumer preferences, businesses can leverage ceramic bowls as a versatile and profitable product in their portfolio.

Ceramic is an excellent choice for bowls, offering durability, aesthetic versatility, and food safety. While challenges like fragility and cost exist, proper sourcing strategies can mitigate these drawbacks. Whether you’re a large-scale retailer or a small business owner, partnering with a trusted supplier like EKA ensures you deliver high-quality ceramic bowls that resonate with your target market.

For inquiries about custom ceramic bowls, contact us today!