In today’s competitive tableware market, choosing the right manufacturing partner can be the difference between success and stagnation. For homeware buyers, giftware wholesalers, and cross-border eCommerce sellers looking to scale or launch custom ceramic bowl collections, Chinese ceramic bowl manufacturers are becoming an increasingly attractive option. From cost efficiency and flexible customization to consistent quality and large-scale capacity, manufacturers in China offer a complete production ecosystem designed to support brand growth.

In this guide, we’ll explore the key benefits of working with ceramic bowl factories in China, compare them with other global production regions, and help you understand how to make the most of such a partnership.

Why Global Buyers Are Turning to Chinese Ceramic Bowl Manufacturers

China has long held its reputation as the world’s ceramic capital. Rooted in centuries of craftsmanship and modernized with smart production lines and sustainable glazing technologies, Chinese factories today serve some of the most iconic tableware brands worldwide.

1. Cost-Effective Yet High-Quality Production

One of the most appealing aspects of sourcing ceramic bowls from China is the favorable cost-to-quality ratio. Labor efficiency, access to local kaolin clay, and integrated production hubs allow manufacturers to keep costs competitive without sacrificing quality.

For example, large bowl orders for restaurants or giftware resellers often benefit from bulk production runs with consistent finishes, which would be cost-prohibitive in European or North American markets.

2. Flexible OEM and ODM Support

Need to launch a line of hand-painted ramen bowls or embossed cereal bowls with your logo? Chinese ceramic bowl suppliers are experienced in both OEM (original equipment manufacturing) and ODM (original design manufacturing). This flexibility means they can:

- Customize glaze colors, shapes, and textures

- Add decals or branding directly on the product

- Adapt packaging for retail, gifting, or drop shipping

3. Shorter Lead Times with Scalable Capacity

Many factories in major ceramics hubs like Chaozhou and Jingdezhen operate on a tiered production system, capable of handling both small batch custom designs and large-scale container orders. Combined with increasingly optimized logistics networks, this ensures faster lead times, especially for seasonal collections or trending styles.

Comparison Table: Ceramic Bowl Manufacturing by Region

To better understand the strategic advantage of Chinese ceramic bowl manufacturers, here’s a comparison with other major production regions:

| Feature / Region | China | Europe (e.g., Portugal, Poland) | Southeast Asia (e.g., Vietnam, Thailand) |

|---|---|---|---|

| Unit Cost (Bulk Orders) | Low to Moderate | High | Moderate |

| Minimum Order Quantity | Low (for custom designs) | High | Moderate |

| Customization Flexibility | High (OEM & ODM capabilities) | Limited to OEM, slower for ODM | Moderate |

| Lead Times | 25–40 days | 60–90 days | 45–60 days |

| Design Innovation | Strong (wide glaze & shape options) | Strong in artisanal style | Moderate |

| Production Scale | Large-scale & scalable | Small to mid-size | Mid-size |

| Global Shipping Access | Excellent (via ports like Shenzhen) | Limited | Good |

4. Ceramic Innovation and Modern Glazing Techniques

Modern ceramic bowl production in China isn’t just about volume—it’s about refined aesthetics and functional quality. From speckled matte glazes to reactive crystalline finishes, suppliers offer a rich palette of surface treatments that cater to both minimalist trends and rustic table settings.

Many factories also offer microwave-safe, dishwasher-safe, and lead-free ceramic options, which appeal to European and North American regulatory standards.

5. Sustainable and Ethical Production

Sustainability is no longer optional. Increasingly, Chinese ceramic factories are adopting eco-friendly kilns, water-recycling systems, and low-emission glazing processes. For buyers looking to market eco-conscious ceramic bowls, this shift allows them to source responsibly while still maintaining price competitiveness.

6. Case Study: 8 Global Brands That Source or Resemble Products Made in China

Here are eight globally recognized brands known for their high-quality ceramic bowls. While not all disclose their factory origins, their design characteristics and production styles align closely with capabilities found in China:

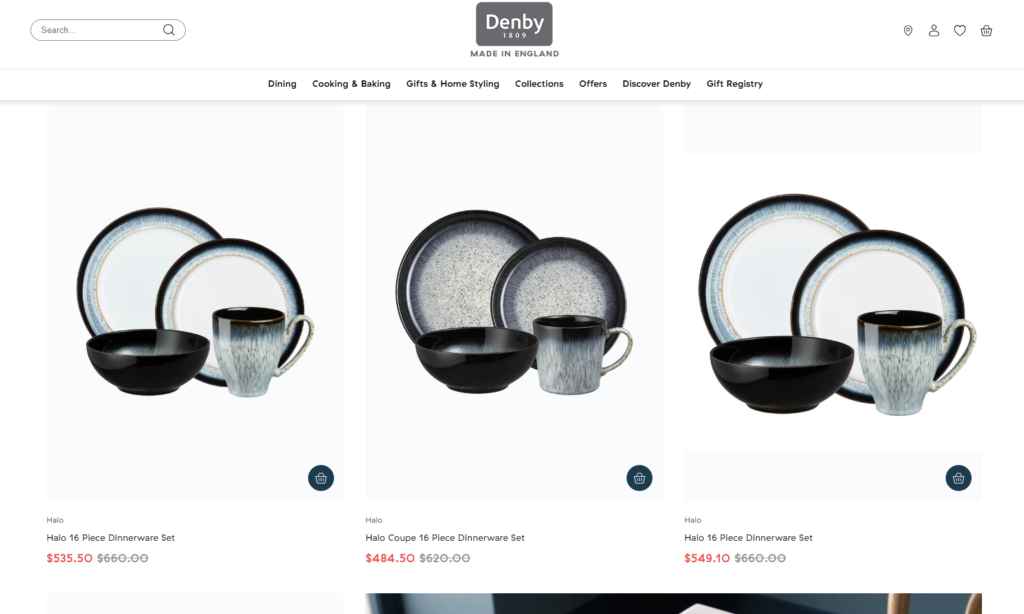

Denby Halo

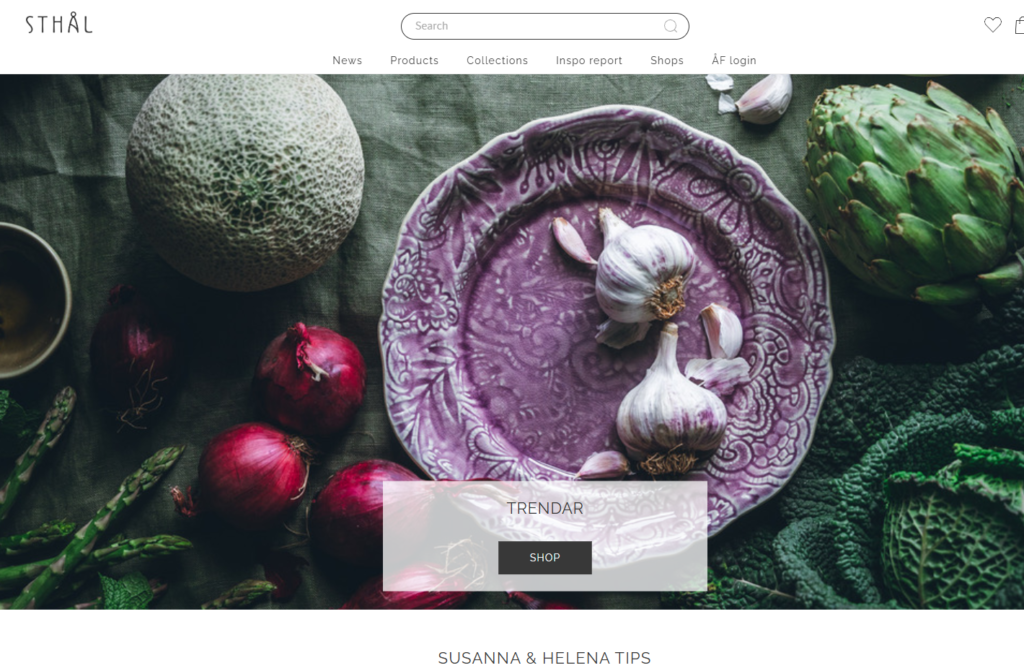

Sthål

| Brand Name | Region | Notable Features |

|---|---|---|

| Denby Halo | UK | Durable stoneware bowls with layered reactive glaze—ideal for hearty meals |

| HKliving | Netherlands | Retro-inspired designs with hand-applied glaze effects; modern take on vintage ceramics |

| Sthål | Sweden | Artisan-style bowls with botanical relief patterns and Mediterranean-inspired glazes |

| Pomax | Belgium | Rustic textures and earth-toned finishes; often seen in contemporary table styling |

| Bitossi Home | Italy | Vibrant color-blocked ceramic bowls blending tradition with playful modernity |

| Rörstrand | Sweden | Classic Nordic ceramic craftsmanship with clean lines and heritage patterns |

| ASA Selection | Germany | Minimalist bowls with a focus on pure shapes and solid matte glaze coatings |

| Salt&Pepper | Australia | Affordable, on-trend ceramic bowls ideal for casual and everyday table settings |

These examples reflect design trends—like speckled finishes, artisan edges, or reactive glaze bowls—that Chinese factories are fully capable of reproducing at scale with customization options.

FAQ: Questions Global Buyers Often Ask

Q1: Are ceramic bowls made in China safe for food use?

Yes. Reputable manufacturers offer lead-free, cadmium-free, and FDA-compliant glazes, especially when exporting to the EU or US markets.

Q2: What is the average MOQ for custom ceramic bowl orders in China?

The average MOQ ranges from 500 to 2000 pieces, depending on the complexity of the design and type of glaze used.

Q3: Can I visit ceramic factories before placing an order?

Absolutely. Many factories welcome in-person visits or offer virtual factory tours via video, especially useful for first-time buyers.

Q4: How do I ensure product quality before mass production?

Most suppliers offer pre-production samples and third-party inspection services. It’s also common to have test runs before full-scale orders.

Q5: How can I customize packaging for retail or online sales?

Chinese factories often provide full packaging solutions, including logo-printed boxes, eco-friendly wraps, and barcode labeling for Amazon or other platforms.

Is Partnering with Chinese Manufacturers Right for Your Brand?

Whether you’re launching a private label kitchenware line or expanding an existing product catalog, partnering with Chinese ceramic bowl manufacturers gives you access to scalable, design-forward, and cost-effective solutions. With support for both OEM and ODM, it’s easier than ever to bring custom concepts to life—whether you’re designing speckled noodle bowls, reactive glaze soup bowls, or embossed rice bowl sets.